Mash Tun Journal

Mash Tun Journal is a paean to craft beer. It follows the pleasures and aesthetics of craft beer and how it intersects with food, culture, and society.

Enjoy some texts from our archive.

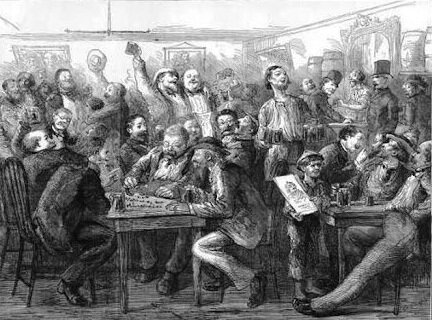

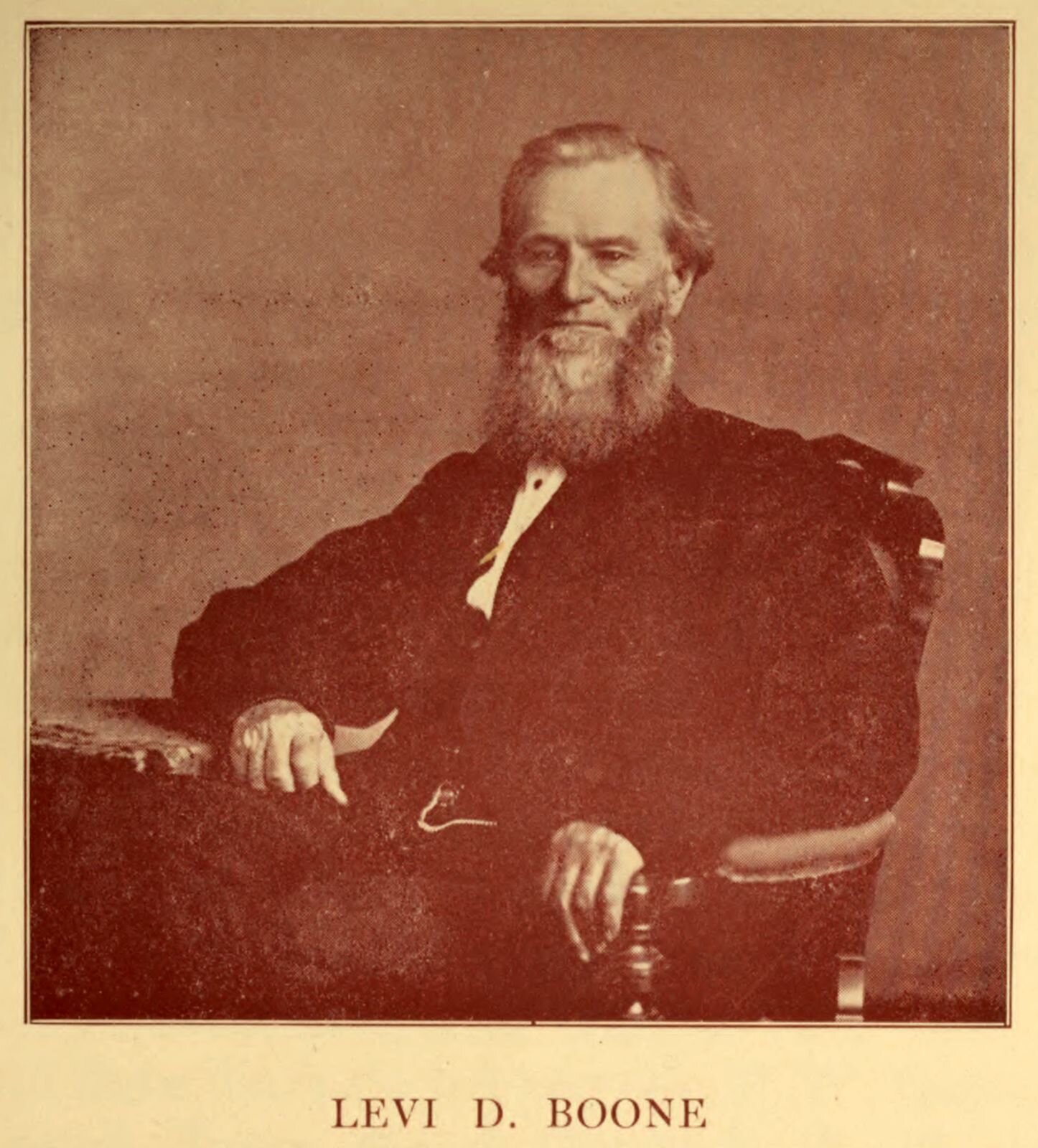

“A Montstrous Doctrine” - Chicago’s Lager Beer Riot

When contemporary commentators are searching for a historical analogue to the Tea Party movement, they often reference the Know-Nothings.

Why Can’t I Taste Beer Online Yet?

Maybe the Cloudy Boy craze is the closest we have gotten to blurring this line between Internet Experience Beer and Actual Beer.

Craft Beer and the Coming Recession

In recent years, there has been no shortage of articles and interviews on the continued expansion of the craft beer industry.

Blue Ribbon Brouhaha?: Beer Battles at the 1893 World's Columbian Exposition

On June 2, 1893 the Adams Express Company delivered safely to Chicago a model of a Milwaukee brewery, built to scale and made of pure gold.

The Artist Craftsman

“Artists” in Plato’s world existed before a concept of “Art” developed as we understand it today.

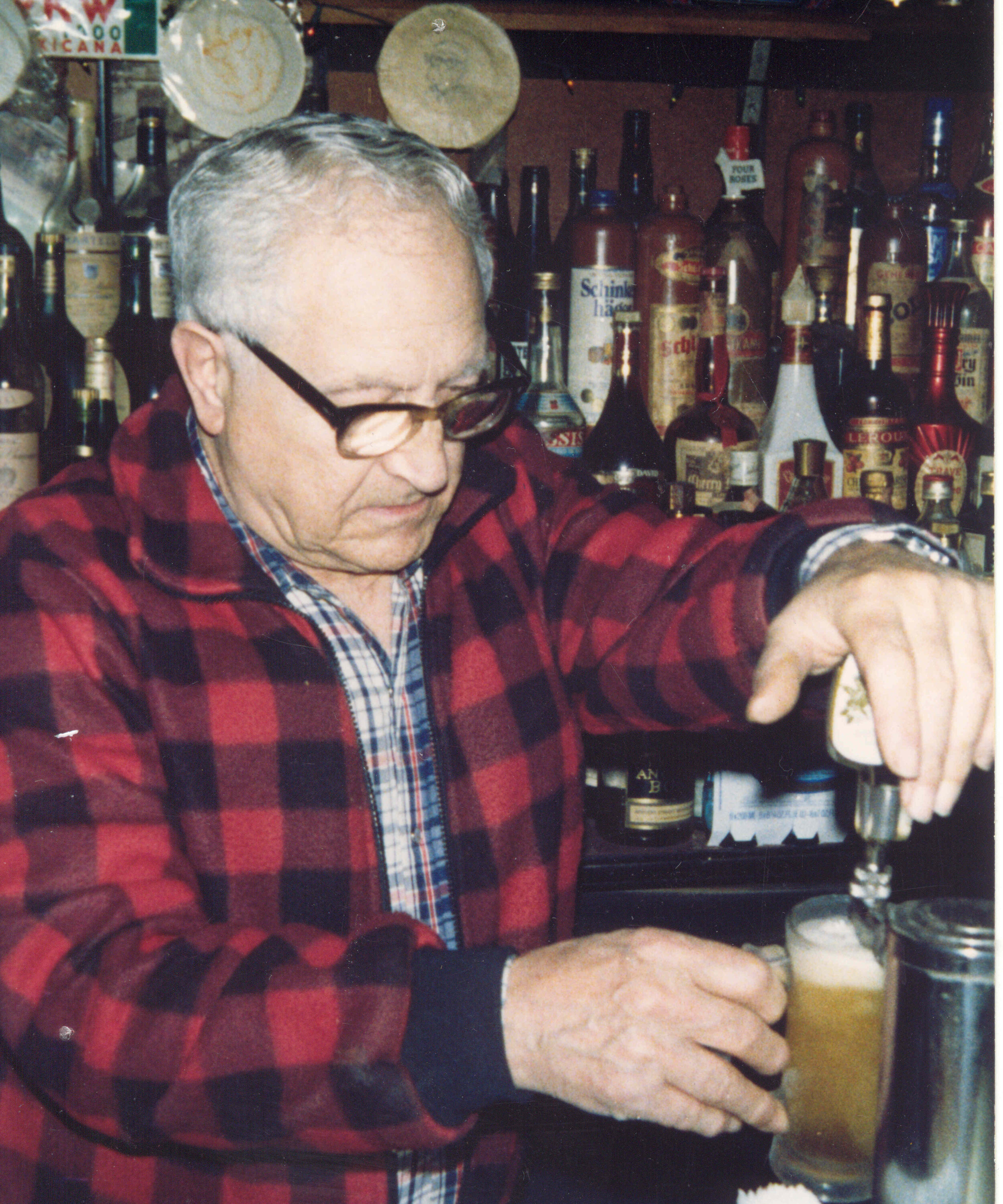

Rememberence of Bars Past: The Bucket O’suds

With the seemingly endless stream of openings of new high-end establishments touting the refined practice of mixology nationwide, it’s hard to remember a time when these practitioners in the art of imbibing were somewhat uncommon and relegated to the everyday status of “bartender”.

Illinois’ Nazi Brewers?: Was Pilsen’s Schoenhofen Brewery A Front?

Old bars gather within them unwritten histories of the neighborhoods that surround them, the stories collected like the odd assortment of bric-a-brac and brewery paraphernalia covering walls and filling the corners.

About Esters

Craft beer is partially defined by the ingredients used in the brewing process. Most craft brewers follow tradition and stick to using water, malt, hops and yeast

Interview: Gerrit Lewis and Beejay Olson of Pipeworks Brewery

Pipeworks is the one of Mash Tun Journal's local heroes.